Inspection: Quality Control Laboratory

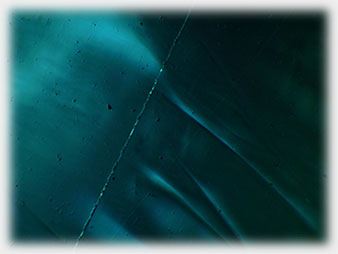

Defects in the sapphire crystals have as volume (gas inclusions, structure defects, etc.) as surface character (scratches, digs, growing structure, etc.).

The quality of all of our manufactured sapphire parts is very important at PST. In our Quality Control Laboratory we have the latest computerized quality control measuring equipment for the inspection of completed sapphire parts. PST are investing in the modern equipment to enable us to inspect manufactured parts to all customers requirements.

Our Quality Inspection process has Manual Inspection and Instrumental Inspection stages. For Tolerances and Dimensions Control we are using computerized Comparison Inspection Method for large quantities. It lets us to make inspection more quickly and accurately.

We are testing sapphire crystal orientation, surface and volume quality by polarized microscope. For measuring flatness and parallelism tests we are using the laser interferometer. Laser interferometer has software, which able to generate Test Report of inspected sapphire parts.

Laboratory capabilities:

- measuring of optical and geometrical parameters: optical axis orientation, diameter of round optical parts and dimensions of square and other parts, thickness

- measuring of surface finish quality in according with MIL and ISO standards

- measuring of TWD (Transmitted Wavefront Distortion) in reflected light beam

- measuring of parallelism of a flat optical parts

- estimating of refractive index inhomogeneity

In order to assure the high quality of our products we provide Certificate of Conformance (COC).

Laser interferometer

Polarized microscope

Volume and surface defects under microscope

Digital caliper and micrometers

Digital caliper

Digital micrometer 0-1 inch